3D Printing Without Supports

- leescott853

- Mar 30, 2023

- 2 min read

Updated: Jan 18, 2024

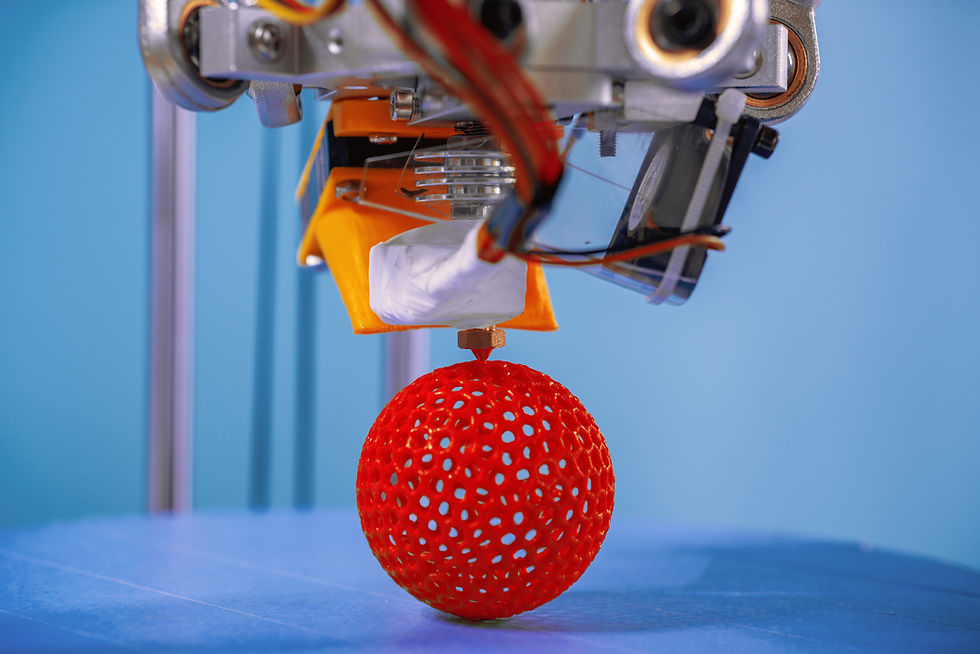

3D printing has revolutionised the way we create and produce objects, allowing us to turn digital designs into physical products with incredible speed and precision. One of the biggest challenges of 3D printing, however, is dealing with support structures. These structures are necessary to prevent the object from collapsing during the printing process, but they can also be time-consuming to remove and can leave unwanted marks or scars on the finished product. At Maker Club, we are always looking for ways to improve our printing process and create the best possible products for our clients. That's why we are excited to share with you the benefits of 3D printing without supports. By designing our products to be 3D printed without supports, we are able to create objects that are not only faster to print, but also require less post-processing. This means that our clients receive their products faster, and they also look better and more professional without any visible support marks or scars. One of the keys to 3D printing without supports is designing the object in such a way that it can be printed without any overhangs or unsupported areas. This can be achieved by using techniques such as adding chamfers, fillets, or draft angles to the design, or by breaking the object up into smaller, printable parts that can be assembled later.

Another important factor is choosing the right printing technology and material. For example, certain materials such as PLA or PETG have better bridging capabilities and can print objects with longer unsupported spans than other materials. At Maker Club, we are constantly exploring new ways to push the boundaries of 3D printing without supports. By using cutting-edge technologies and composites, we are able to create objects that are not only beautiful and functional, but also incredibly strong and durable. In conclusion, 3D printing without supports is an exciting development in the world of 3D printing, and at Maker Club, we are proud to be at the forefront of this technology. By designing our products with this in mind, we are able to create stunning and professional-looking objects that our clients are proud to display on their promotional videos and social media channels. If you're looking for high-quality 3D printed parts, look no further than Maker Club.

_edited_edited_.png)

Comments